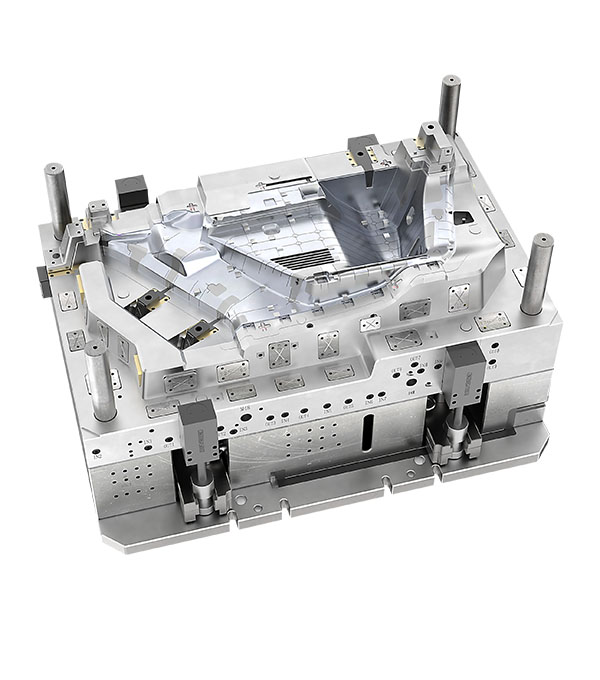

Tianhui Mold is a professional maker for automotive sidewall molds, car sidewall molds, automobile sidewall molds and vehicle sidewall molds in China. Our services include prototyping, tooling, sampling, pilot run, mass production and assembly.

For sidewall mold making, we often give you this suggestion:

Core and cavity steel: Up to customer’s budget and productivity required, we suggest the following steel grade: Pre- harden steel : P20 (1.2311), P20+Ni…etc Harfen Steel : H13 (1.2344) / NAK80…etc. Stainless steel : ASSAB Stavax…etc

Steel of Mold Base:Up to customer’s budget and requirement , we suggest different mold base steel to clients. Normal used material S50C, or P20

Hardness of Cavity & Core:Pre-Hardenss Steel : HRC 30~32+-1* Heat Treatment Steel : HRC 50~52+-1*

Core pulling or Ejection system: Depends on the Products. Commonly used :Motor , oil cylinder, stripping plate, angel pin, ejector pin…etc

Mold Accessories: Compatible to DME/ HASCO Standard.

Cooling System:In Core : Baffle or By pass cooling ;In Cavity Plate: Chain drilling type cooling

Surface Finish: Up to the product’s requirement, Normal used : Texture, EDM machining , Polishing

Mold Life: Up to mold steel grade, under ideal operation condition, 1. Pre-harden steel, min. 20~300000 shots 2. Harden / heat treatment steel : 60~800000 shots. 3. Stainless steel : 1 million shots.

Runner: 1. Cold runner 2. Hot runner 3.cold runner +hot runner

Delivery time: 80~90 days , presenting T1 samples

Packing: Standard Wooden Case

Production: We can also provide Pilot Run production and molding production